Our goal is to provide you with the ideal coating for your application as efficiently as possible, using a streamlined, straightforward process.

ISURTEC is strongly committed to research and development, with an interdisciplinary team of scientists and engineers focused on developing new coated products for the scientific and medical communities. Our research is supported by the National Institutes of Health (NIH) through the Small Business Innovative Research Program (SBIR).

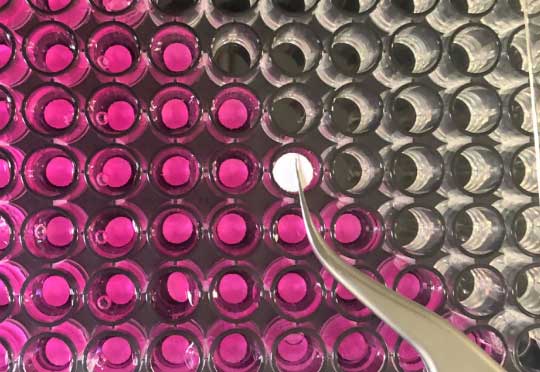

Did you know that 50% of patients with ureteral stents experience complications such as painful encrustation and infections? Over time, ureteral stents and other devices in the urological tract can become encrusted with calcium and magnesium salts. ISURTEC’s innovative anti-encrustation coating has demonstrated the ability to reduce calcium deposition by over 80% after just one month. This significant advancement represents a major improvement in patient well-being. A heartfelt thanks to our dedicated team for its efforts and the NIH SBIR program for funding this groundbreaking research (NIH-R44DK097934).

Uncoated PU Ureteral Stent

ISURTEC-coated PU Ureteral Stent

Ureteral stents and other devices in the urological tract can encrust with Ca2+ and Mg2+ salts over time. ISURTEC’s anti-encrustation coating reduces Ca2+ deposition > 80% after 1 month.

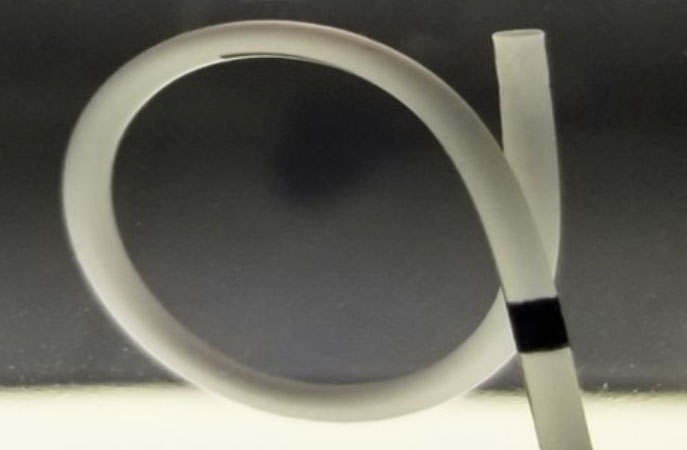

Over 30% of implantable cerebrospinal fluid (CSF) shunts used to treat hydrocephalus fail within the first year. Shunt failure necessitates surgical reintervention, which, if delayed, can lead to severe consequences, including brain damage or death. Implantable silicone shunts have been used successfully for decades to treat this disorder. While silicone is a well-established and biocompatible material for implantation, the primary, often unaddressed, cause of shunt failure is clogging due to embolism and tissue ingrowth. Through funding provided by the NIH SBIR Program, ISURTEC is developing a novel coating designed to reduce shunt failure by minimizing cell and tissue adhesion to the shunt material. By improving the longevity and reliability of CSF shunts, we hope to enhance patient outcomes and reduce the need for repeated surgical interventions (NIH-R44NS119007).

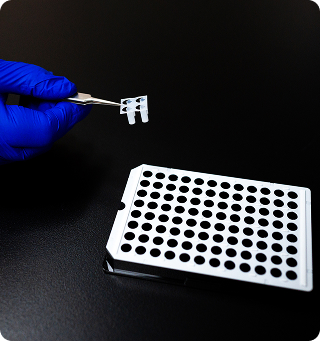

ISURTEC has developed cell culture inserts with a nanofiber membrane for growing cells in a more in vivo-like environment. The topography of our electrospun membranes mimics the extracellular matrix that cells excrete around themselves as they mature. Cells can be seeded in suspension in the insert cup or bioprinted on the insert underside. The nanofiber membranes are electrospun from either permanent materials, such as PET growth surfaces, or materials that biodegrade over time. Biodegradable membranes allow cells to be grown on both the apical and basolateral sides of the insert membrane eventually forming a mature barrier membrane as the insert membrane degrades. Please inquire if you are interested in beta testing ISURTEC cell culture inserts!

ISURTEC works with companies internationally to craft solutions for difficult surface modification and coating challenges. From basic idea to a commercial solution with tight specifications, we will collaborate with you to design and implement a solution, then support your technology transfer.

ISURTEC developed PHOTOPRIME SR 330 Primer to bond hydrophilic coating to a broad range of medical and biotech devices. This technology has found additional uses as an adhesion layer across a number of interesting applications, including drug eluting catheters and, in this case, lab-on-a-chip technology.

Silicone rubber is increasingly used in medical devices, implantables, and wearables due to its biocompatibility, flexibility, and stability in the body, as well as its lack of leachable chemicals. Silicone rubber is relatively easy to manufacture and form into complex shapes, further lending to its draw as a key medical device material. But when it comes to applying a lubricious coating to silicone rubber, challenges arise.

A mid-size medical device manufacturer approached ISURTEC about coating a new device with our commercial lubricious coating. However, the company did not yet have prototypes of their devices, which would be produced from polymer sheeting. The client asked us to not only coat the sheeting, but produce prototypes by laser cutting and heat-sealing their CAD designs. While ISURTEC does not manufacture medical devices, our engineering lab can assist with prototyping. We successfully delivered two different designs within weeks. The client was then able to use them for physician evaluations in a non-clinical setting. These coated prototypes set the stage for production of the coated device.

A mid-size international medical device manufacturer came to ISURTEC seeking a hydrophilic coating for their balloon catheters, which were composed of several grades of PEBAX, transitioning to nylon with a polyurethane balloon. ISURTEC conducted a feasibility study, coating five catheters, including the balloon portion and the distal 10 inches, with our commercial ISURGLIDE® 460 coating over PHOTOPRIME® 955 primer. We tested one of the catheters by staining the coating to demonstrate uniformity and measuring the coefficient of friction of the hydrated coating (COF < 0.02). Satisfied with their internal testing of the coated balloon catheters, the client was ready to move forward with manufacturing, but lacked a coating service or internal coating capabilities in their home country. To assist them, ISURTEC provided technology transfer on both the coating equipment and the coating procedure we used on their catheters. The client was then able to build their own equipment and commercially produce the ISURGLIDE®-coated balloon catheters.

In addition to performing government and customer research, ISURTEC is proud to perform internal research – which has resulted in impressive technology.

Innovative hydrophilic primer + topcoat with excellent durability.

ISURTEC is a technology innovator with a deep passion for identifying, creating and commercializing new methods and products that enable companies to fulfill their mission.

Certified to the ISO 9001:2015 Standard by the Systems Certification Body an IAPMO Company

Innovative Surface Technologies, Inc.

1045 Westgate Drive Suite 100

Saint Paul, MN 55114

651-209-9757

ISURTEC will consistently provide high quality products and services that meet requirements for medical device coatings and other scientific coatings. We will actively strive to bring excellence to the surface in all that we do, meeting or exceeding customers’ needs and expectations, and improve the quality of our products and service by enabling each employee to fulfill their job responsibilities correctly the first time.

The following are trademarks of ISURTEC: ISURTEC®, ISURGLIDE®, ISURLITE®, ISURTHERM®, ISURCOAT®, PHOTOPRIME®, ISURGLIDE™, ISURBLOCK™, ISURCELL™. All rights are expressly reserved.