With multifunctional laboratories, as well as dedicated manufacturing facilities, our research and development capabilities include synthesis of new chemicals, development of coating technologies, testing of coatings at a biological interface such as cells, bacteria or tissue, and more.

ISURTEC has a team of scientists focused on molecular biology research, as well as routine cell culture. Our dedicated cell culture facility consists of a laminar biosafety cabinet level II, and two dedicated temperature-controlled incubators connected to carbon dioxide tanks which provide an optimum environment for growing cells.

Primary Cell Lines

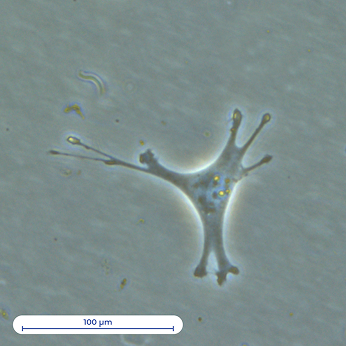

ISURTEC handles primary cell lines routinely including rat myoblasts, rat astrocytes, bovine aortic endothelial cells, and human dermal fibroblasts. In addition, we work with dissociated rat brain cultures for drug development applications.

Stem Cells

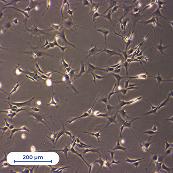

ISURTEC does routine mesenchymal stem cell culturing. hMSCs have been successfully cultured on ISURTEC’s proprietary nanofiber scaffolds and used in many of our internal projects.

Neural Cell Lines

ISURTEC has expertise working with hiPSC-derived neural progenitor cells. These progenitors have been used successfully for differentiating into neurons and glia of the human cortex region. Apart from this, we also culture iPSC-derived human astrocytes, and glutamatergic and GABAergic neurons.

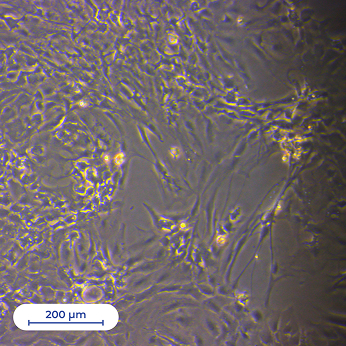

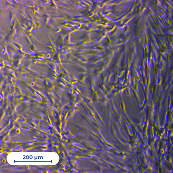

Adherent Cell Culture

ISURTEC specializes in culturing, seeding and passaging adherent cultures such as human dermal fibroblasts for regular experiments.

Organoid Culture

ISURTEC has the capability to form organoids using ISURTECs ISURCELL® ULA (Ultra Low Attachment) plates. Cortical brain organoids, human mesenchymal stem cell organoids, human colorectal cancer organoids and human dermal fibroblast organoids have been produced successfully at ISURTEC’s cell culture facility.

Cancer Cell Lines

ISURTEC works with human colorectal carcinoma cell lines and has expertise growing and passaging HeLa cells as well.

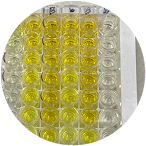

We have expertise in designing, performing and interpreting ELISAs. Currently focused on in-house R&D of a line of synthetic combination passivating/chemically activating coatings known collectively as ISURBLOCK®. ISURBLOCK® solution can act both as a non-animal sourced BSA substitute and as a platform for chemically bonding biomacromolecules that are components of the ELISA assay.

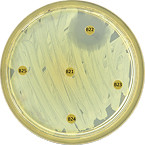

At ISURTEC, we perform microbiological assays on our coated surfaces. We test for adherence of microbes to the surface as well as microbicidal effects of drug release. The image to the left is a Kirby-Bauer zone of inhibition test demonstrating a bacteria-free zone from moxifloxacin release in the upper section of a Mueller-Hinton plate with E. coli.

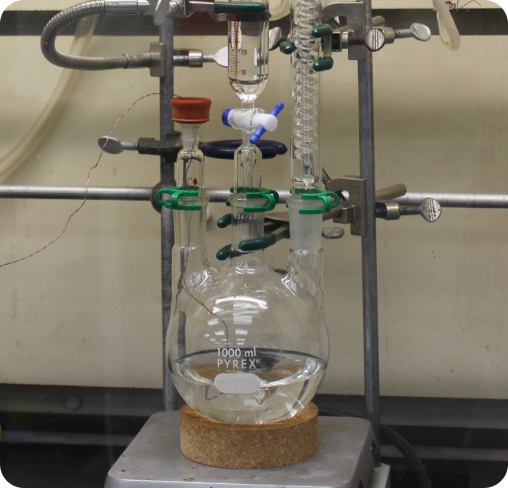

At ISURTEC, we have a fully functional wet lab for small molecule and polymer synthesis. We design our own synthetic routes and perform reactions on a bench scale. We have in-house GPC, FTIR, and UV/fluorescence spectrophotometry for characterization, as well as access to the nearby University of Minnesota facilities. We specialize in photoreactive small molecules and polymers.

Photochemistry uses light to cause chemical reactions. All things absorb different wavelengths of light, giving them their color. The energy in that light can also be used to break and reform chemical bonds if the light and the chemical are chosen correctly.

An example of this type of reaction is a photoinitiator. After absorbing light, a chemical bond can break homolytically to form two radicals. The radicals can react with monomers to polymerize or they can react with another radical to reform covalent bonds.

Similarly, other photoreactive molecules can absorb light to enter an excited state in which they act as pseudo-diradicals. In this state the molecules can abstract hydrogen atoms, creating radicals on otherwise unreactive molecules. If the radicals are on a polymer or polymeric substrate, they can recombine, forming covalent bonds in a process called crosslinking. These new carbon-carbon bonds are strong and provide durability to the crosslinked material.

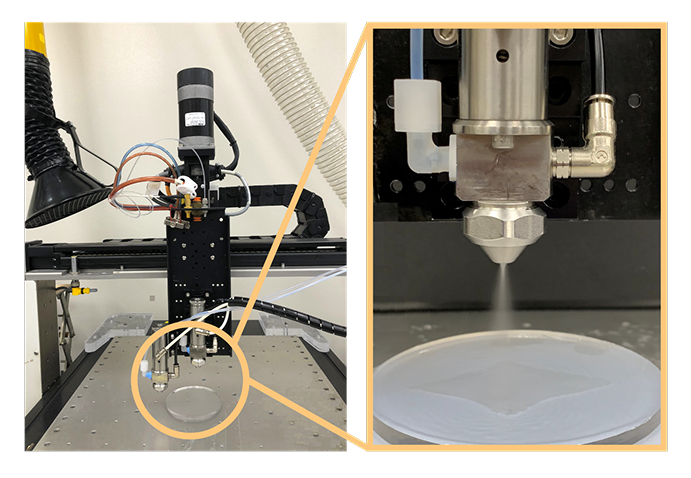

With in-depth knowledge of process design and coating engineering, ISURTEC can tailor our coating methods to meet exacting requirements. In our in-house coating suite, we use linear motion machines, including dip and spray application, multiple light sources (UVA, UVB, and UVC), and measuring equipment to standardize each step.

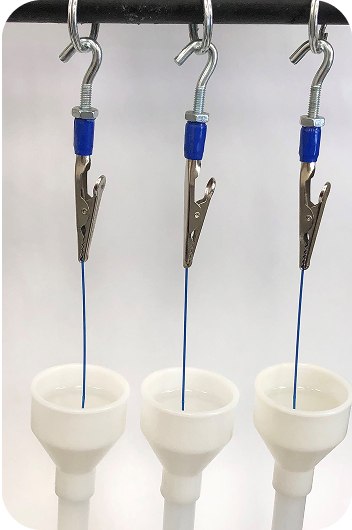

Dip Coating Method

Spray Coating Method

At ISURTEC, we have successfully coated catheters (PTCA, balloon, drainage, urinary, etc.), guidewires, stents, shunts, and many other types of medical devices of various geometries. Common substrates include: PEBAX, nylon, polypropylene, polyethylene (HDPE, LDPE), polystyrene, polyurethane, PVC, PEEK, silicone rubber, as well as glass and metal substrates.

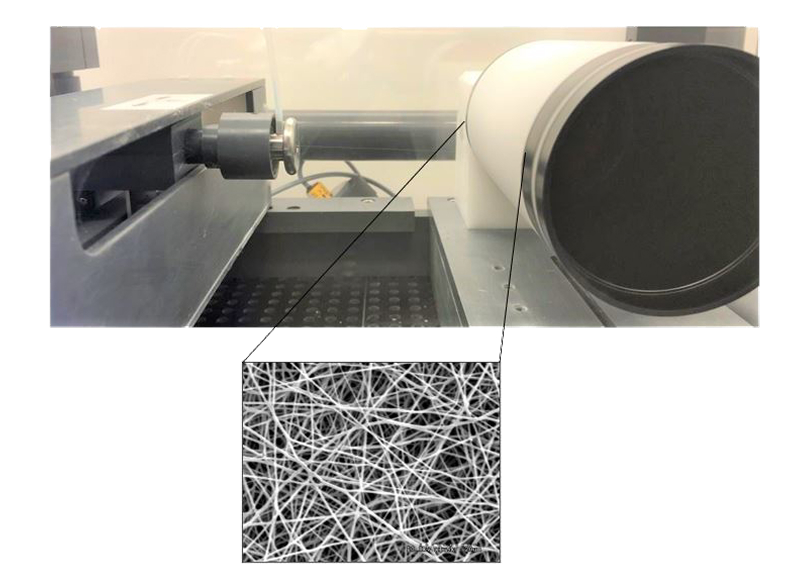

Electrospinning is a manufacturing technique that produces polymer fibers for tissue engineering and membrane production. ISURTEC has in-house electrospinning apparatus that fabricate nano– to microfibrillar membranes and scaffolds. We develop aligned and randomly oriented, non-woven electrospun membranes for research including drug development scaffolds and photo-reactive nanofibers.

ISURTEC has a climate-controlled electrospinning apparatus that can fabricate a range of fiber diameters and orientations from both natural and synthetic fibers.

The electrospinning technique utilizes an applied current to “draw” long, thin threads from a charged polymer solution

The mandrel (right) rotates and the nozzle (left) horizontally translates as a jet of polymer solution travels from the nozzle to the mandrel via applied high voltage. The solution reaches the mandrel as a polymer fiber to create a non-woven scaffold (pop-out).

Range of Polymers: Natural and Photoreactive (using ISURTEC’s photochemistry)

ISURTEC is a technology innovator with a deep passion for identifying, creating and commercializing new methods and products that enable companies to fulfill their mission.

Certified to the ISO 9001:2015 Standard by the Systems Certification Body an IAPMO Company

Innovative Surface Technologies, Inc.

1045 Westgate Drive Suite 100

Saint Paul, MN 55114

651-209-9757

ISURTEC will consistently provide high quality products and services that meet requirements for medical device coatings and other scientific coatings. We will actively strive to bring excellence to the surface in all that we do, meeting or exceeding customers’ needs and expectations, and improve the quality of our products and service by enabling each employee to fulfill their job responsibilities correctly the first time.

The following are trademarks of ISURTEC: ISURTEC®, ISURGLIDE®, ISURLITE®, ISURTHERM®, ISURCOAT®, PHOTOPRIME®, ISURGLIDE™, ISURBLOCK™, ISURCELL™. All rights are expressly reserved.